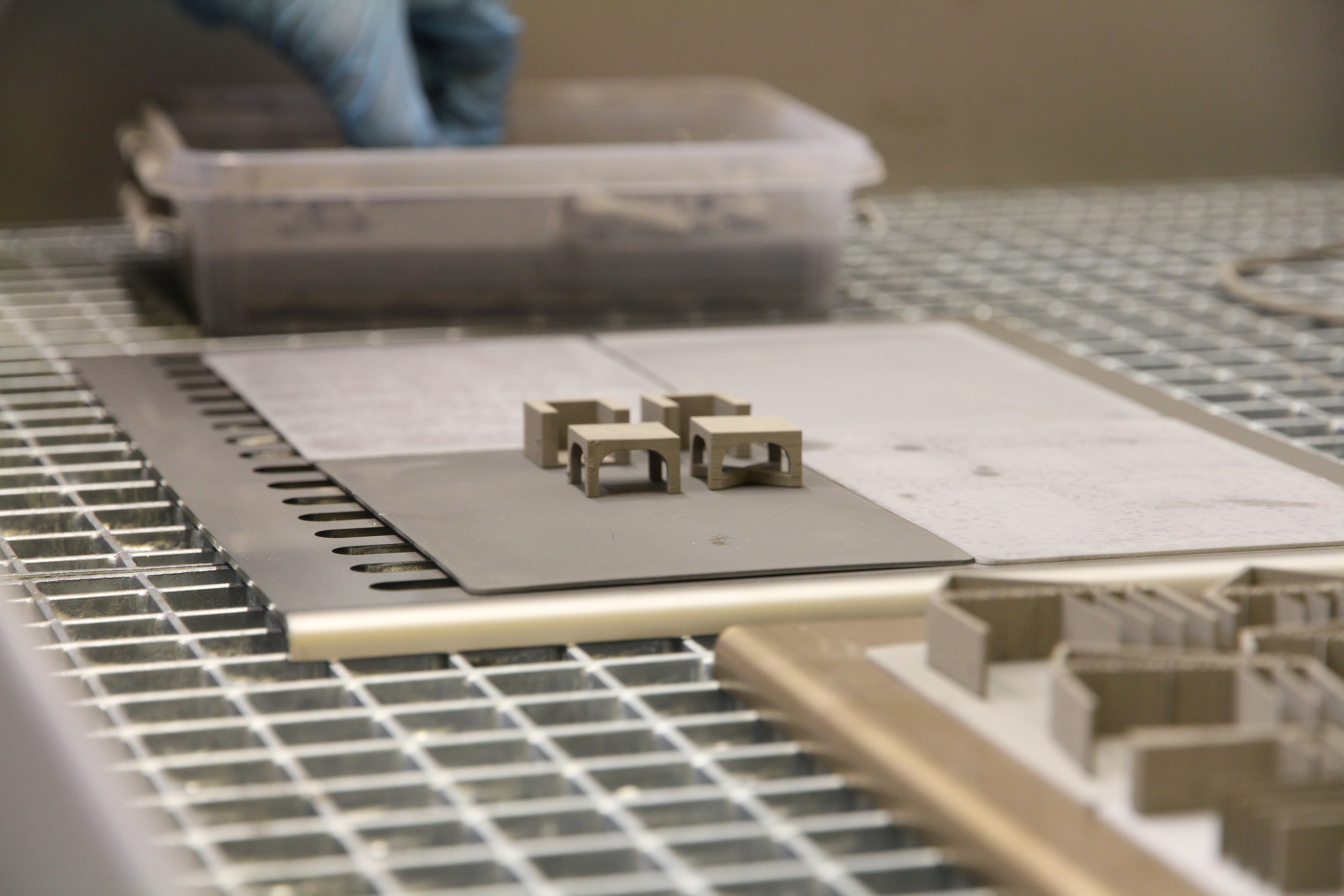

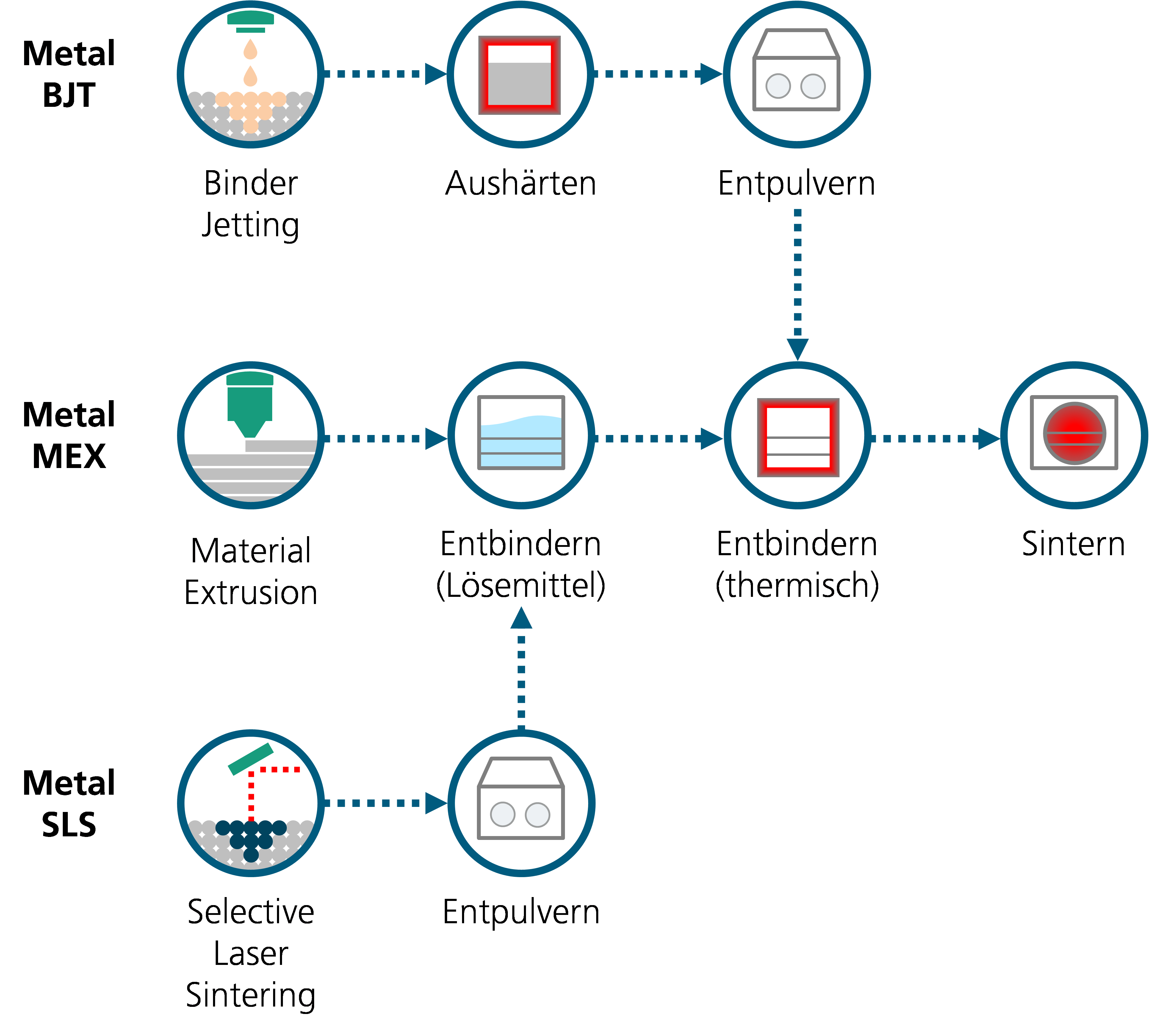

All three Sinter-AM processes share the common feature that they begin with an additive shaping process. This results in so-called green parts, where the metal powder is held in shape using a binder system.

Depending on the process and binder system, the additively manufactured green parts exhibit different strengths, which are always lower than the final strengths achieved after sintering.

Between the sintering and shaping processes, a debinding step is always carried out to remove the binder system used for shaping. The debinding process can vary depending on the method but always concludes with a thermal process.

Following debinding, the sintering process takes place, during which the metal powder is densified, and the fundamental material properties are established.